Author Affiliations

Abstract

1 Institute of Micro-nano Photonics & Beam Steering, School of Science, Nanjing University of Science and Technology, Nanjing 210094, China

2 Centre for Disruptive Photonic Technologies, The Photonics Institute, School of Physical and Mathematical Sciences, Nanyang Technological University, Singapore 637371, Singapore

3 College of Physics and Electronic Information Science, Tianjin Normal University, Tianjin 300387, China

4 e-mail: jly@njust.edu.cn

5 e-mail: zexiang@ntu.edu.sg

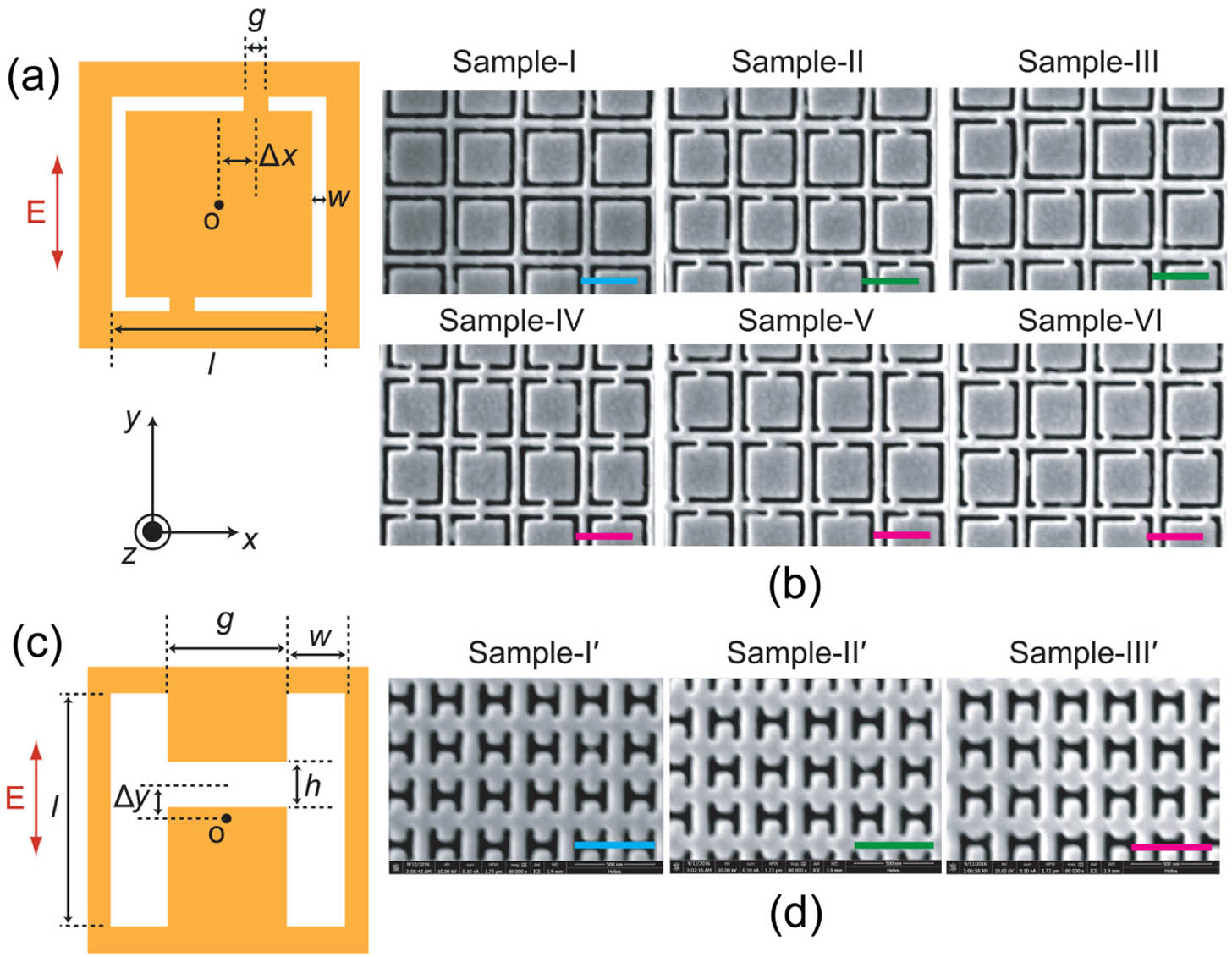

Understanding the mode’s origin in planar metamaterials is fundamental for related applications in nanophotonics and plasmonics. For complex planar metamaterials, conventional analysis that directly obtains the final charge/current distribution of a mode is usually difficult in helping to understand the mode’s origin. In this paper, we propose a mode evolution method (MEM) with a core analysis tool, i.e., plasmonic evolution maps (PEMs), to describe the mode evolution in several complementary planar metamaterials with designed plasmonic atoms/molecules. The PEMs could not only clearly explain a mode’s origin, but also reveal the role of a structure’s symmetry in the mode formation process. The MEM with PEMs can work as a simple, efficient, and universal approach for the mode analysis in different kinds of planar metamaterials.

Photonics Research

2021, 9(1): 01000073

Author Affiliations

Abstract

1 Institute of Applied Physics and Computational Mathematics, Beijing 100088, China

2 Research Center of Laser Fusion, Chinese Academy of Engineering Physics, Mianyang 621900, China

3 Center for Applied Physics and Technology, Peking University, Beijing 100871, China

4 Collaborative Innovation Center of IFSA, Shanghai Jiao Tong University, Shanghai 200240, China

5 China Academy of Engineering Physics, Mianyang 621900, China

The octahedral spherical hohlraums have natural superiority in maintaining high radiation symmetry during the entire capsule implosion process in indirect drive inertial confinement fusion. While, in contrast to the cylindrical hohlraums, the narrow space between the laser beams and the spherical hohlraum wall is usually commented. In this Letter, we address this crucial issue and report our experimental work conducted on the SGIII-prototype laser facility which unambiguously demonstrates that a simple design of cylindrical laser entrance hole (LEH) can dramatically improve the laser propagation inside the spherical hohlraums. In addition, the laser beam deflection in the hohlraum is observed for the first time in the experiments. Our 2-dimensional simulation results also verify qualitatively the advantages of the spherical hohlraums with cylindrical LEHs. Our results imply the prospect of adopting the cylindrical LEHs in future spherical ignition hohlraum design.

Spherical hohlraum Laser propagation Cylindrical laser entrance hole Laser spot movement Matter and Radiation at Extremes

2016, 1(1): 2

Author Affiliations

Abstract

1 Institute of Applied Physics and Computational Mathematics, Beijing 100088, China

2 Research Center of Laser Fusion, Chinese Academy of Engineering Physics, Mianyang 621900, China

3 Center for Applied Physics and Technology, Peking University, Beijing 100871, China

4 Collaborative Innovation Center of IFSA, Shanghai Jiao Tong University, Shanghai 200240, China

5 China Academy of Engineering Physics, Mianyang 621900, China

Corrigendum Text: On page 2 of this letter, there is a misprint in the unit. The unit of the geometrical dimension of the spherical hohlraums on this page should always be “mm” rather than “mm”, i.e. in the second paragraph, “…with 800 J per beam at 0.35 mm…” should be “…with 800 J per beam at 0.35 μm…”, “The slit of 400 mm width is parallel…” should be “The slit of 400 μm width is parallel…”, “The laser focal diameter is about 500 mm…” should be “The laser focal diameter is about 500 μm…”; in the third paragraph, “…we take 850 μm as the radius…” should be “…we take 850 mm as the radius…”, “The LEH radius RL is 400 mm…” should be “The LEH radius RL is 400 μm…”, “…the radius of the cylindrical LEH outer ring is taken as 1.5 RL = 600 mm” should be “…the radius of the cylindrical LEH outer ring is taken as 1.5 RL = 600 μm”. This mistake does not affect any of the main results of the original letter.

Matter and Radiation at Extremes

2016, 1(2): 133

1 四川大学 原子与分子物理研究所,成都 610065

2 中国工程物理研究院 激光聚变研究中心,四川 绵阳 621900

为解决快点火分解物理研究中锥丝靶的整体成型问题,基于超精密车削技术,提出了制备无缝、无胶锥丝靶的方法。通过建立的Au丝超精密切削成型过程中的微切削力模型,研究了相关工艺条件下微切削力对锥丝靶成型的影响。采用有限元分析方法和实验验证手段研究多种参数Au丝的切削变形问题,获得了微切削力条件下Au丝的变形规律。研究结果表明:微切削力对丝径 10 μm附近锥丝靶的成型影响较大,对丝径更大的锥丝靶则无明显影响。

惯性约束聚变 快点火 锥丝靶 超精密车削 切削力 ICF fast ignition cone-wire targets diamond turning cutting force 强激光与粒子束

2015, 27(9): 092002

中国工程物理研究院 激光聚变研究中心, 四川 绵阳 621900

基于贝叶斯理论, 针对小批量、少样本的金柱腔生产过程, 讨论了生产质量控制模型的建立方法。利用大量历史数据和少量样本信息, 建立了金柱腔车削工序的质量控制模型, 并利用实际生产数据对该模型进行了验证。验证结果显示, 当前金柱腔车削工序的生产过程处于统计控制状态, 质量控制模型没有发出生产质量的虚警报, 建立的质量控制模型是有效的, 能够指导金柱腔车削工序的实际生产。

金柱腔 贝叶斯分析 质量控制 golden hohlraum Bayessian method quality control 强激光与粒子束

2014, 26(2): 022015

中国工程物理研究院 激光聚变研究中心, 四川 绵阳 621900

选取纯度较高的1100铝棒作为加工模芯的原材料,利用金刚石车床精加工出表面粗糙度均方根值小于20 nm的铝模芯,采用磁控溅射的方法在铝模芯上制备厚度大于5 μm的铜防护层,得到铝铜复合芯轴。对制备的铜防护层的表面微观结构、结晶性能、厚度一致性进行了分析测试,结果表明磁控溅射法制备的铜防护层沿(111)面择优生长,表面粗糙度均方根值小于30 nm,厚度一致性优于95%,圆柱度小于1 μm。镀层与基底结合力强,可满足大厚度黑腔涂层的制备需求。

惯性约束聚变 铝铜复合芯轴 磁控溅射 表面粗糙度 结晶性能 inertial confinement fusion Al/Cu hybrid mandrel magnetron sputtering surface roughness crystallinity 强激光与粒子束

2013, 25(12): 3255

中国工程物理研究院 激光聚变研究中心, 四川 绵阳 621900

采用超精密车削技术加工微尺度正弦波调制曲面微结构,解决了尖刃金刚石刀具刃磨和刀具对中等关键技术,研究了进给量、背吃刀量和主轴转速等主要切削参数对铜模板表面粗糙度的影响规律。加工出波长为(20~150)μm±0.5 μm﹑峰谷高度差为(0.2~20)μm±0.1 μm的带正弦波调制曲面。采用原子力显微镜对模板表面轮廓扫描,在20 μm×20 μm的范围内,其表面粗糙度均方根值小于10 nm。将正弦波调制曲面测量结果与理论轮廓进行比较,采用最小二乘寻优算法评定轮廓误差。完成了曲面轮廓的功率谱表征,利用加工的曲面微结构制备了平面调制靶,实现正弦波调制曲面轮廓的精确转移。

瑞利-泰勒不稳定性 平面调制靶 超精密车削 功率谱 Rayleigh-Taylor instability surface perturbation target ultra-precision turning power spectrum

中国工程物理研究院 激光聚变研究中心, 四川 绵阳 621900

采用单点金刚石车削技术制备加工铝楔形靶,发现金刚石车削加工楔形靶实际轮廓为圆锥面。通过Veeco NT1100白光干涉仪对表面轮廓及粗糙度进行了测量,结果表明平面部分表面粗糙度小于50 nm,最大峰谷值小于100 nm,斜面部分表面粗糙度小于200 nm。分析认为斜面部分粗糙度测量数值较大是由刀具工作角度变化导致的,而测量轮廓线非圆锥体母线又导致粗糙度测量结果大于实际值。

楔形靶 金刚石车削 冲击波 稳定性 wedge target diamond turning shockwave stability

Author Affiliations

Abstract

1 Institute of Modern Optics, Key Laboratory of Optoelectronic Information Science and Technology, Ministry of Education of China, Nankai University, Tianjin 300071, China

2 School of Electrical and Electronic Engineering, Nanyang Technological University, Nanyang Avenue 639798, Singapore

3 Nankai University Affiliated Hospital, Tianjin 300121, China

An optimized iterative technique combining the merits of conventional Gerchber-Saxton (G-S) and adaptive-additive (A-A) algorithms to design multilevel computer-generated holograms for the creation of a desirable structured intensity pattern for multiple optical manipulation is theoretically adopted. Optical trap arrays are demonstrated with the help of liquid crystal spatial light modulator and a microscopic optical tweezer system. Additionally, continuous locked-in transport and deflection of microparticles with the generated optical lattice is proven experimentally. The proposed method possesses apparent high efficiency, high uniformity, and dynamic and reconfigurable advantages.

计算全息图 光学捕获 光学分选 空间光调制器 120.4610 Optical fabrication 350.4855 Optical tweezers or optical manipulation Chinese Optics Letters

2011, 9(6): 061202

中国工程物理研究院 激光聚变研究中心,四川 绵阳 621900

针对惯性约束聚变(ICF)物理实验对具有微加工能力低密度CH泡沫材料的需求,介绍了对二乙烯基苯泡沫的高内相乳液(HIPE)法制备工艺,并讨论了引发剂含量、乳化剂含量、苯乙烯的比例和无机添加剂等对泡沫形貌结构的影响,获得了低密度对二乙烯基苯泡沫的优化制备配方。不同密度对二乙烯基苯泡沫的形貌结构、力学性能和加工性能的表征结果表明:所得泡沫由开孔状球形孔构成,球形孔的直径在1~10 μm之间,孔壁上具有直径为0.2~2.0 μm的圆形孔洞结构;在密度为50 mg/cm3时,泡沫具有5 MPa的弹性模量;通过微加工技术能够获得ICF所需柱状和片状低密度泡沫微靶样品,样品最小尺寸可达100 μm。

高内相乳液法 对二乙烯基苯 微加工性 低密度泡沫 high internal phase emulsion p-divinylbenzene micro-machinability low density foams